ELECTRIC ACTUATOR

PRODUCT FEATURES

1. Continuously track valve position at all times, regardless of power supply.

2. Maintain normal operation and accessibility of graphical interface, remote indication and data logger after power loss.

3. Oil bath lubrication provides long life and the ability to be installed in any direction.

4. Waterproof protection that does not rely on terminal cover and interface seals - double seal structure, protection grade reaches IP68.

5. Independent torque and valve position sensors are used to greatly enhance safety performance.

6. The selection of remote manual control station can realize remote operation configuration and commissioning, with a maximum distance of up to 100 meters.

7. Safe, motor-independent handwheel device, which can be used at any time.

8. It provides detailed trend analysis and diagnostic data for asset management.

9. Upgrade configuration and change control and indication options on site through Bluetooth setter.

10. The screen can display real-time valve and actuator performance status information.

11. Quick and safe commissioning and configuration without power supply through non-invasive intrinsically safe Bluetooth setter.

12. Removable thrust base for easy installation and maintenance.

13. Explosion-proof options meet various international standards.

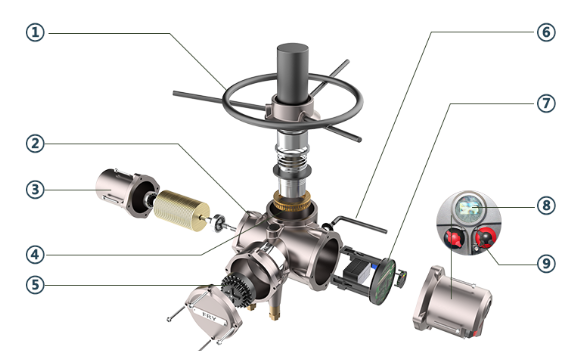

PRODUCT STRUCTURE

1.Handwheel

The sturdy handwheel provides reliable emergency manual operation in the event of power failure.

2. Shell

The high-quality aluminum alloy shell is compact and lightweight. It is coated with a layer of protective material to adapt to extremely harsh environments, and other types of layers are available as needed.

3. Motor

The low inertia and high torque motor allows the motor to quickly reach peak torque after starting, and there is almost no over-limit movement when it is off-excitation. There is a precise temperature switch embedded in the motor coil, which is not affected by the surrounding ambient temperature and keeps the motor in optimal thermal capacity. At the same time, the motor shaft and worm are independent of each other for quick replacement.

4. Worm gear

The worm gear transmission chain is simple, with exquisite structure and constant transmission efficiency. It has a mechanical self-locking function and does not require brakes. The transmission part is filled with long-lasting lubricating oil and can operate for a long time without maintenance.

5. Double-sealed design

The double-sealed design provides a sunflower terminal box that is separated from the control room and sealed. Even if the connection box cover is opened on site, it can ensure the isolation of the inside of the actuator from the outside world, so that moisture, dust, and hazardous gases cannot enter the actuator interior in the slightest, and the internal components are fully protected.

6. Manual/electric switch handle

The manual/electric switch handle can be operated safely at any time. While pressing the handle with appropriate force, slowly turn the handwheel to allow the internal clutch to engage the gear. The clutch will automatically disengage when the motor is energized and in the electrically locked state.

7. Output torque measurement system

A professionally designed useful power measurement system is used as the output torque measurement system. This system is developed from familiar electric energy measurement technology and can obtain accurate and repeatable torque measurement values that are independent of changes in frequency, voltage and temperature.

8. Control panel

The control panel LCD can provide instantaneous, up-to-date status and valve position, with Chinese and English languages available, using an intuitive menu structure to provide calibration and diagnostic information, including torque curves, operation and fault records, motor status, local information and hardware data, etc.

9. Button

The local control "Open"/"Close" buttons and the padlocked "Local"/"Stop"/"Remote" mode buttons all use isolated magnetic transmission Hall effect devices, with no through-shafts and good sealing performance, while eliminating the trouble that can be caused by faulty and fragile reed switches.

APPLICATIONS

ELECTRIC VALVES

DESIGN FEATURES

1. Convenient and safe commissioning configuration

• Fast and safe commissioning configuration, which can be performed without power supply; multi-language human-machine interactive display is provided

• Non-intrusive settings can be performed in any environment

• Detachable thrust base for easy installation and maintenance of valves

• Operation, configuration and commissioning through remote manual control station, with a maximum distance of 100 meters

• Part-turn actuator provides automatic limit setting function

2. Technological advancement

• Position: The latest patented absolute encoder. The encoder adopts a non-contact design and has redundancy and self-detection capabilities. • Display: The advanced double-layer display provides users with large-character valve position display

• Torque: The actuator uses torque sensing technology

• Control: Control elements such as mainboards or bus control boards, actuators and fieldbus communications, use a bus-based internal communication system. This not only reduces wiring and internal connections but also increases reliability.

3. Reliability

• Advanced absolute position measurement to detect real-time continuous position without power

• Graphical interface, remote indication and data logger function after loss of main power

• Dustproof and waterproof, and does not rely on terminal cover and gland - double seal structure, protection level up to IP68

• Independent torque and valve position sensor

• Handwheel operation is safe and always independent of the motor

• Drive shaft bushing uses sealed bearings - maintenance-free

4. Asset management

• Screen can display real-time information of valves and actuators

• Safe and reliable data download through intrinsically safe setting tool

• Upgrade and configure control and indication in the field through setting tool

• Compatible with digital control and monitoring systems and other fieldbus systems

• Detailed trend analysis, diagnostics and data logging can be displayed on the screen or downloaded through the setting tool

5. Optimal preventive maintenance

• Actuators are equipped with a precision data logger that can provide data capture and analysis for valve position.

6. Indication power supply

• Because of the use of absolute encoder, no display battery is required to sense and track valve position. All settings are safe even without power.

7. Safe manual operation

8. Remote field operation

• Use standard data cable, the maximum distance from the actuator is 100 meters

• It can be mounted on a wall or bracket

• Powered by the connected actuator

• Optional explosion-proof type

• Protection grade IP68

• Double seal structure

• Simple setting

• Actuator data records can be displayed and downloaded locally

9. Temperature protection

• In order to prevent the motor from overheating, we have equipped the motor winding with a temperature sensor to directly sense the motor temperature and connect it to the actuator control circuit.

10. Automatic self-diagnosis

11. Instantaneous reversal protection

12. Phase synchronization

13. Valve blockage protection

14. Configurable main interface

• Valve position information and status

• Valve position information and torque value (digital)

• Valve position information and torque value (analog image)

• Valve position information and command information (digital or analog image)

COMMUNICATION PROTOCOL

The electric actuator supports Profibus Dp and has the following features:

Support Profibus Dp-V0.Dp-V1.Dp-V2 functional level

High-speed data exchange (up to 1.5Mbit/s - corresponding to approx. 0.3ms/actuator)

Cable length is about 10Km (the length between two actuators is about 1200m)

About 126 devices can be attached

Redundant linear topology as an option

For Profibus Dp, the basic topology is through RS485 segment tree structure, as shown in the figure:

The electric actuator supports Modbus RTU and has the following features:

Fast data exchange (up to 115Kbit/s - corresponding to approx. 30ms/actuator)

Cable length reaches approximately 10km (1200m without intermediate relay between two actuators)

About 247 devices can be attached

Redundant linear topology as an option

For Modbus RTU, the basic topology is through RS485 segment tree structure, the same as Profibus Dp.

The HART communication protocol adopts the frequency shift keying (FREQUENCY SHIFT KEYING, FSK) principle, which is based on the BELL 202 communication standard. Digital signals are represented by two frequencies: 1200HZ represents logic "1", and 2200HZ represents logic "0". Since the average component of the frequency signal is zero during communication, it will not affect the transmission of analog signals. Therefore, the sine waves of these two frequencies can be superimposed on the DC4~20MA analog signal and transmitted simultaneously. In this way, not only the DC4-20MA analog signal can be used, but also the same cable can be used to realize two-way multi-information transmission with digital signals, thus having functions such as modifying the range, damping time, PID parameters, etc., which can improve the operation quality and management efficiency of the system.

PRODUCT DISPLAY

TECHNICAL PARAMETERS

FRYQ+BW technical parameters

|

Model |

Torque (NM) |

Rotating speed (r/min) |

Motor power (KW) |

Rated current (A) |

Jam current (A) |

90°rotation time (S) |

Weight (KG) |

|

FRYQ18+BW1 |

1000 |

0.68 |

0.21 |

1.70 |

4.65 |

22 |

95 |

|

1700 |

0.34 |

0.21 |

1.75 |

6.00 |

44 |

95 |

|

|

FRYQ18+BW2 |

3000 |

0.68 |

0.64 |

3.70 |

12.00 |

22 |

140 |

|

3000 |

0.34 |

0.78 |

5.90 |

16.50 |

44 |

140 |

|

|

FRYQ18+BW3 |

4000 |

0.68 |

0.64 |

3.70 |

12.00 |

22 |

185 |

|

5000 |

0.34 |

0.75 |

5.90 |

16.50 |

44 |

185 |

|

|

FRYQ18+BW4 |

7800 |

0.68 |

1.50 |

9.30 |

37.00 |

22 |

200 |

|

7800 |

0.34 |

1.19 |

5.90 |

26.50 |

44 |

200 |

|

|

FRYQ25+BW5 |

8500 |

0.8 |

1.50 |

9.30 |

37.00 |

19 |

240 |

|

10000 |

0.4 |

1.19 |

5.90 |

26.50 |

38 |

240 |

|

|

FRYQ25+BW6 |

12000 |

0.8 |

2.14 |

15.00 |

70.00 |

19 |

370 |

|

17500 |

0.4 |

1.91 |

11.00 |

40.00 |

38 |

370 |

|

|

FRYQ35+BW7 |

13000 |

0.74 |

2.14 |

15.00 |

70.00 |

20 |

450 |

|

20000 |

0.37 |

1.91 |

11.00 |

40.00 |

40 |

450 |

|

|

FRYQ35+BW8 |

32000 |

0.73 |

4.29 |

24.00 |

135.00 |

21 |

500 |

|

63500 |

0.36 |

5.81 |

35.00 |

80.00 |

41 |

500 |

DIMENSIONS

FRYQ+BW direct mounted

FRYQ+BW foot-plate mounted

FRYQ+BW dimensions (direct mounted)

|

Model |

D |

D1 |

D2 |

D3 |

D4 |

E |

F |

K |

H |

H1 |

H2 |

n-MD |

h |

Output torque |

|

FRYQ18+BW1 |

φ328 |

φ45 |

φ125 |

/ |

φ162 |

20 |

94 |

14 |

558 |

295 |

258.5 |

4-M12 |

/ |

1000 |

|

FRYQ18+BW2 |

φ328 |

φ60 |

φ140 |

/ |

φ178 |

25 |

87 |

18 |

603 |

295 |

258.5 |

4-M16 |

/ |

1600 |

|

FRYQ18+BW3 |

φ328 |

φ70 |

φ165 |

/ |

φ210 |

25 |

95.5 |

20 |

685 |

295 |

258.5 |

4-M20 |

/ |

2500 |

|

FRYQ18+BW4 |

φ328 |

φ70 |

φ165 |

/ |

φ210 |

30 |

92 |

20 |

739 |

295 |

258.5 |

4-M20 |

/ |

4000 |

|

FRYQ25+BW5 |

φ642 |

φ70 |

φ165 |

/ |

φ218 |

25 |

103 |

2-20 |

900 |

324 |

357 |

4-M20 |

/ |

6000 |

|

FRYQ25+BW6 |

φ642 |

φ75 |

φ254 |

φ200 |

/ |

25 |

165 |

2-20 |

877 |

324 |

357 |

8-M16 |

5.5 |

8000 |

|

FRYQ35+BW7 |

φ780 |

/ |

φ254 |

φ200 |

/ |

25 |

165 |

2-20 |

1102 |

338 |

357 |

8-M16 |

5.5 |

10000 |

|

FRYQ35+BW8 |

φ780 |

/ |

φ254 |

φ200 |

/ |

25 |

165 |

2-20 |

1102 |

338 |

357 |

8-M16 |

5.5 |

15000 |

FRYQ+BW dimensions(foot-plate mounted)

|

Model |

A1 |

A2 |

A3 |

A4 |

A5 |

C |

D1 |

D2 |

N-φd1 |

Output torque |

|

FRYQ18+BW1 |

240 |

280 |

150 |

190 |

120 |

170 |

200 |

250 |

2-φ20 |

1000 |

|

FRYQ18+BW2 |

375 |

435 |

175 |

235 |

195 |

170 |

200 |

250 |

2-φ20 |

1600 |

|

FRYQ18+BW3 |

500 |

560 |

180 |

240 |

210 |

230 |

200 |

250 |

2-φ30 |

2500 |

|

FRYQ18+BW4 |

500 |

560 |

180 |

240 |

210 |

230 |

200 |

250 |

2-φ30 |

4000 |

|

FRYQ25+BW5 |

480 |

540 |

260 |

320 |

200 |

267 |

350 |

/ |

φ36 |

6000 |

|

FRYQ25+BW6 |

600 |

670 |

250 |

320 |

320 |

300 |

400 |

/ |

φ40 |

8000 |

|

FRYQ35+BW7 |

600 |

670 |

250 |

320 |

320 |

300 |

400 |

/ |

φ40 |

10000 |

|

FRYQ35+BW8 |

600 |

670 |

250 |

320 |

320 |

300 |

400 |

/ |

φ40 |

15000 |

GEARBOX SPECIFICATIONS

Manual operators feature alloy steel worm shafts and bronze worm gears.

Both buried and submersible operators feature corrosion-resistant input shafts.

All operators, except buried operators, feature valve position pointers as standard.

Handwheels are optional and available in a variety of sizes.

All sizes can be supplied with factory-installed electric valve actuators or can be easily converted to electric operation in the field using electric actuators.

The operating speed of electric butterfly, plug or ball valves can be adjusted over a wide range, limited only by the motor speed and the available gear ratios.

General specifications

|

Operator |

Ratio |

Output torque |

Input torque for output torque rating |

Maximum one-time input torque |

|||

|

ft-lb |

Nm |

ft-lb |

Nm |

ft-lb |

Nm |

||

|

BW-0 |

71 |

445 |

605 |

21 |

28 |

100 |

136 |

|

BW-1 |

70 |

1300 |

1764 |

62 |

84 |

600 |

814 |

|

BW-1/S2.86 |

200 |

1300 |

1764 |

24 |

33 |

230 |

312 |

|

BW-2 |

70 |

2200 |

2985 |

105 |

142 |

675 |

915 |

|

BW-2/S2.86 |

200 |

2200 |

2985 |

41 |

56 |

260 |

353 |

|

BW-3 |

70 |

5650 |

7667 |

269 |

365 |

510 |

692 |

|

BW-3/S2.86 |

200 |

5650 |

7667 |

105 |

142 |

200 |

271 |

|

BW-4 |

60 |

12800 |

17370 |

711 |

964 |

1290 |

1749 |

|

BW-4/S6 |

360 |

12800 |

17370 |

132 |

179 |

240 |

325 |

|

BW-5 |

65 |

19583 |

26575 |

1004 |

1361 |

1830 |

2481 |

|

BW-5/S6 |

390 |

19583 |

26575 |

186 |

252 |

340 |

461 |

|

BW-6 |

66 |

46000 |

62425 |

2323 |

3150 |

3900 |

5288 |

|

BW-6/S13.6 |

898 |

46000 |

62425 |

205 |

278 |

319 |

433 |

|

BW-7 |

69 |

63333 |

85945 |

3060 |

4149 |

6600 |

8950 |

|

BW-7/S19.2 |

1325 |

63333 |

85945 |

191 |

259 |

375 |

509 |

|

BW-7M |

50 |

93000 |

126204 |

6200 |

8407 |

10000 |

13560 |

|

BW-7M/S19.2 |

960 |

93000 |

126204 |

388 |

526 |

613 |

831 |

Input shaft splines

|

Product |

Input shaft splines (w/o SGAs) |

Input shaft splines (w/ SGAs) |

|

BW-0 |

15 involute splines, 16/32 D.P., 0.9375" Pitch Dia. |

Not Applicable |

|

BW-1, 2, 3 |

6 splines, 1.05" Root Dia., 0.310" wide, 1.250" O.D. |

6 splines, 1.05" Root Dia., 0.310" wide, 1.250" O.D. |

|

BW-4, 5 |

6 splines, 1.525" Root Dia., 0.430" wide, 1.750" O.D. |

6 splines, 1.05" Root Dia., 0.310" wide, 1.250" O.D. |

|

BW-6 |

28 involute splines, 12/24 D.P., 2.333" Pitch Dia. |

6 splines, 1.05" Root Dia., 0.310" wide, 1.250" O.D. |

|

BW-7, 7M |

3.750" dia., keyway 7 ⁄8 x 7 ⁄16 x 3.00" long |

6 splines, 1.05" Root Dia., 0.310" wide, 1.250" O.D. |

FACTORY PICTURES

Hot Tags: ball valve electric actuator ip68, China, manufacturers, suppliers, factory, buy, price, quotation, Motor Operated Butterfly Valve, Linear Electric Actuator For Rotork, Electric Actuator For Bernard, Air Damper Valve, On Off Type Electric Actuator, Angular Travel For Rotork Actuator